د ۲۰ ملي میتر مایکرو سټیپر موټور د ګیربکس سره مل کیدی شي

تفصیل

دا دایمي مقناطیس سټیپر موټور 20 ملي میتر قطر لري، د 60gf.cm تورک لري، او کولی شي د 3000rpm اعظمي سرعت ته ورسیږي.

دا موټور په ګیربکس کې هم اضافه کیدی شي، د موټرو د ګام زاویه 18 درجې ده، دا په هر انقلاب کې 20 ګامونه دي. کله چې ګیربکس اضافه شي، د موټرو د سستیدو اغیزې د گردش زاویه ریزولوشن کولی شي 0.05 ~ 6 درجو ته ورسیږي. د ډیری اړتیاو لپاره د تطبیق وړ، د گردش موقعیت دقیق کنټرول.

د موټرو د کویل مقاومت 9Ω/فیز دی، او دا د ټیټ ډرایو ولټاژ (شاوخوا 5V DC) لپاره ډیزاین شوی. که چیرې پیرودونکی غواړي چې موټر په لوړ ولټاژ کې چلوي، موږ کولی شو د کویل مقاومت د هغې سره سمون لپاره تنظیم کړو.

سربیره پردې، د موټرو په پوښ کې دوه M2 پیچونه شتون لري، دوی د ګیر بکس سره د فکس کولو لپاره کارول کیږي. پیرودونکي کولی شي د دې موټرو نورو برخو ته د فکس کولو لپاره هم پیچونه وکاروي.

د دې نښلونکی 2.0 ملي متره پیچ (PHR-4) دی، او که پیرودونکي وغواړي موږ کولی شو دا بل ډول ته بدل کړو.

له همدې امله، دا محصول کارول کیدی شي چیرې چې دقیق موقعیت کنټرول ته اړتیا وي. دا عموما په طبي تجهیزاتو، پرنټرونو، اتومات تجهیزاتو، روبوټونو او نورو کې کارول کیدی شي.

پیرامیټونه

| د موټرو ډول | بایپولر مایکرو سټیپر موټور |

| د مرحلې شمېر | دوهم پړاو |

| د ګام زاویه | ۱۸ درجې/قدم |

| د باد مقاومت (25℃) | ۱۰Ωیا ۳۱Ω/پړاو |

| ولټيج | ۶ وی ډي سي |

| د موټر چلولو حالت | ۲-۲ |

| د پیل اعظمي فریکونسي | ۹۰۰ هرټز (لږترلږه) |

| د غبرګون اعظمي فریکونسي | ۱۲۰۰ هرټز (لږترلږه) |

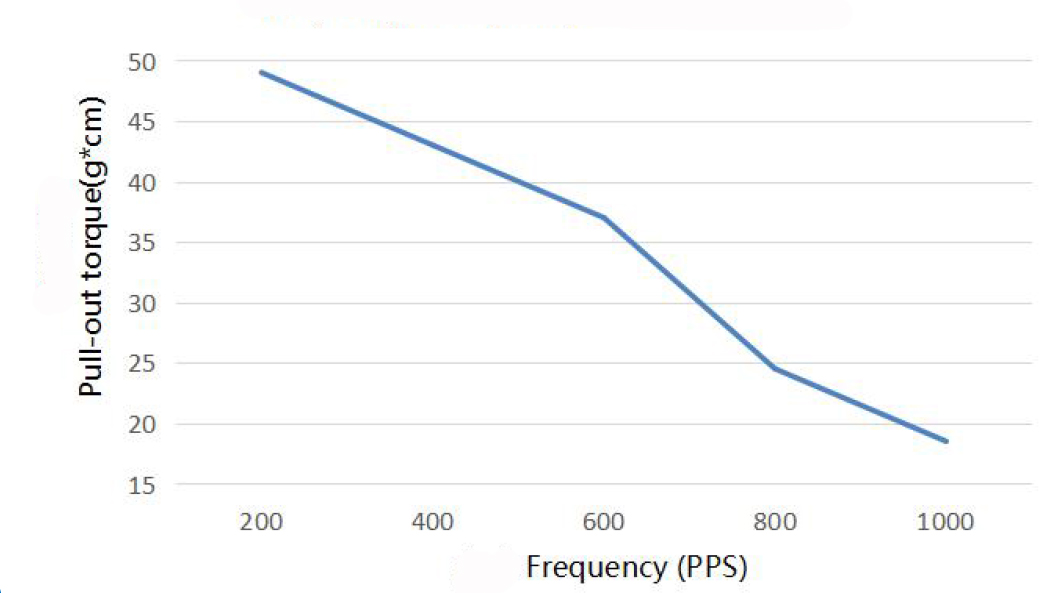

| د وتلو تورک | ۲۵ ګرامه سانتي متره (۶۰۰ پی پی ایس) |

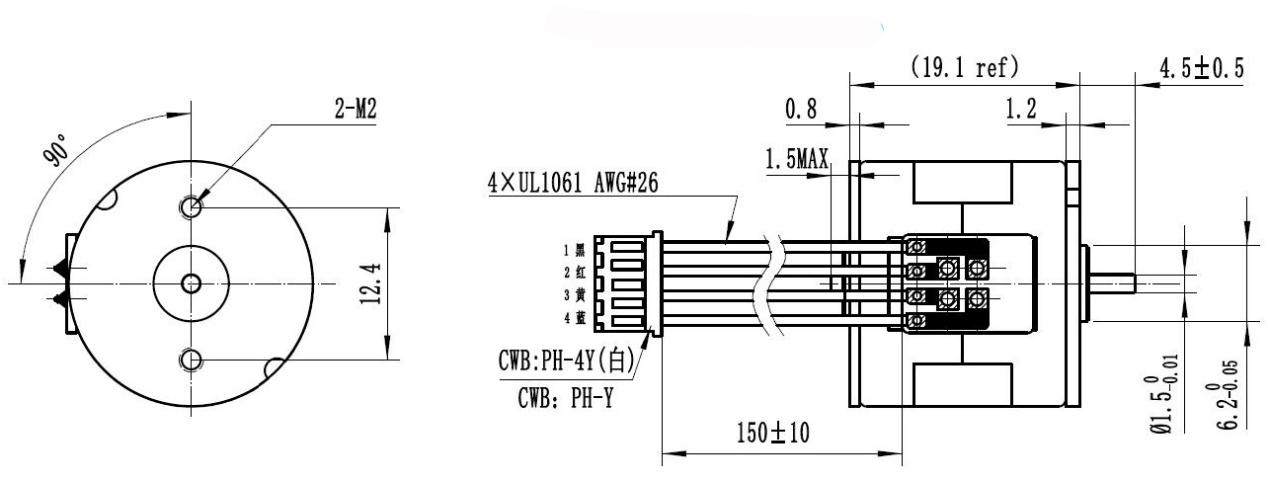

د ډیزاین انځور

د تورک په مقابل کې د فریکونسۍ ډیاګرام

د هایبرډ سټیپر موټور کارول

ځانګړتیاوې او ګټه

۱. لوړ دقت موقعیت

څرنګه چې سټیپرونه په دقیقو تکراریدونکو ګامونو کې حرکت کوي، دوی په هغو غوښتنلیکونو کې غوره دي چې دقیق اړتیا لري

موقعیت، د هغو ګامونو شمیر سره چې موټر حرکت کوي

2. د لوړ دقیق سرعت کنټرول

د حرکت دقیق زیاتوالی د پروسې لپاره د گردش سرعت غوره کنټرول ته هم اجازه ورکوي.

اتومات او روبوټکس. د څرخېدو سرعت د نبضونو د فریکونسۍ له مخې ټاکل کیږي.

۳. د وقفې او ساتلو فعالیت

د ډرایو کنټرول سره، موټور د قلف فعالیت لري (د موټور د بادونو له لارې جریان شتون لري، مګر

موټور نه ګرځي)، او لاهم د تورک تولید ساتل کیږي.

۴. اوږد ژوند او ټیټ الکترومقناطیسي مداخله

سټیپر موټور برشونه نلري، او د برش شوي برش په څیر د برشونو لخوا لیږدولو ته اړتیا نلري

ډي سي موټور. د برشونو هیڅ رګونه نشته، کوم چې د خدماتو ژوند زیاتوي، بریښنایی چنګکونه نلري، او بریښنایی مقناطیسي مداخله کموي.

د مایکرو سټیپر موټور کارول

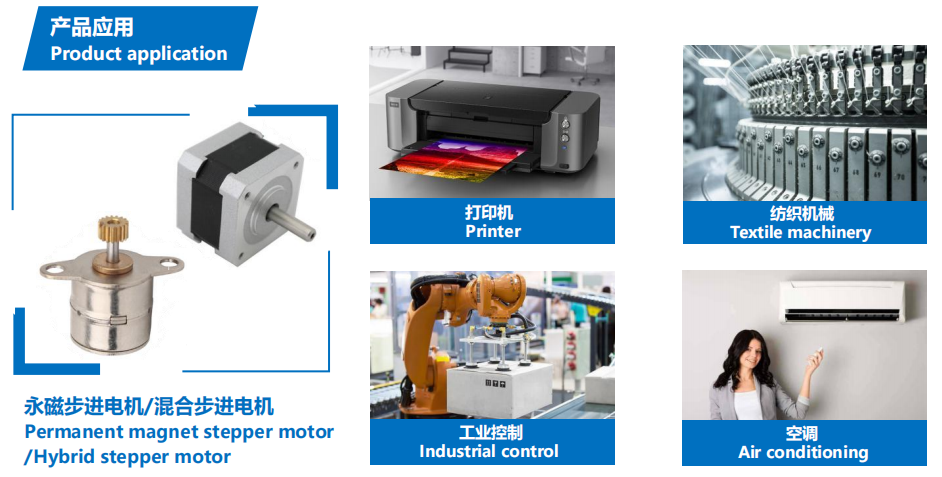

چاپګر

د ټوکر ماشینونه

صنعتي کنټرول

د هوا کنډیشن

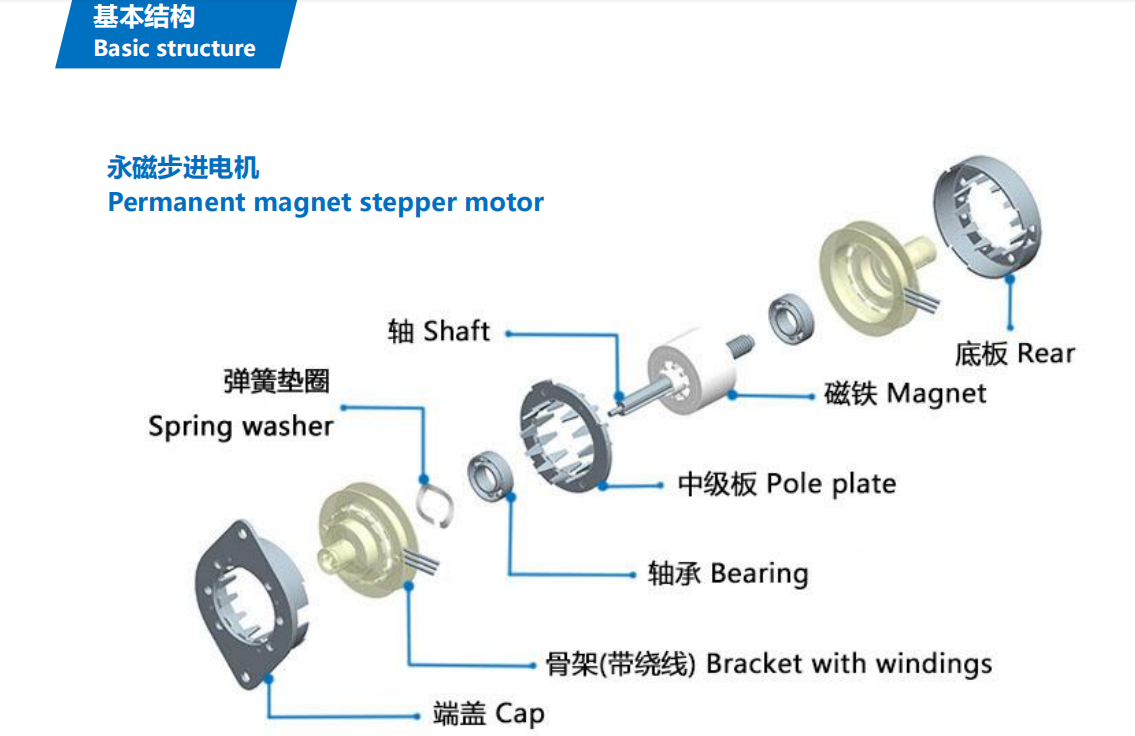

د سټیپر موټور د کار اصل

د سټیپر موټور ډرایو د سافټویر لخوا کنټرول کیږي. کله چې موټور د ګرځیدو اړتیا ولري، ډرایو به

د سټیپر موټرو نبضونه تطبیق کړئ. دا نبضونه د سټیپر موټرو ته په یو ټاکلي ترتیب کې انرژي ورکوي، په دې توګه

د موټرو روټر په یوه ټاکلي لوري (د ساعت په لور یا د ساعت په مقابل لوري) کې د څرخیدو لامل کیږي. ترڅو

د موټرو مناسب گردش درک کړئ. هرکله چې موټر د موټر چلوونکي څخه نبض ترلاسه کړي، نو دا به د ګام زاویه (د بشپړ ګام ډرایو سره) سره وګرځي، او د موټرو د گردش زاویه د چلول شوي نبضونو شمیر او د ګام زاویه لخوا ټاکل کیږي.

مخکښ وخت

که موږ په سټاک کې نمونې ولرو، موږ کولی شو نمونې په 3 ورځو کې واستوو.

که موږ په سټاک کې نمونې نلرو، موږ باید هغه تولید کړو، د تولید وخت شاوخوا 20 تقویم ورځې دي.

د ډله ایز تولید لپاره، د لیډ وخت د امر مقدار پورې اړه لري.

بسته بندي

نمونې په فوم سپنج کې د کاغذ بکس سره بسته شوي، د ایکسپریس لخوا لیږدول کیږي

په پراخه کچه تولید، موټرې په نالیه شوي کارتنونو کې د شفاف فلم سره بهر بسته شوي دي. (د هوا له لارې لیږدول)

که چیرې د سمندر له لارې ولیږدول شي، محصول به په پالټونو کې بسته شي

د تادیې طریقه او د تادیې شرایط

د نمونو لپاره، په عمومي توګه موږ پے پال یا علی بابا منو.

د ډله ایز تولید لپاره، موږ د T/T تادیه منو.

د نمونو لپاره، موږ د تولید دمخه بشپړ تادیه راټولوو.

د ډله ایز تولید لپاره، موږ کولی شو د تولید دمخه 50٪ دمخه تادیه ومنو، او پاتې 50٪ تادیه د بار وړلو دمخه راټول کړو.

وروسته له دې چې موږ له 6 ځله څخه ډیر امر وکړو، موږ کولی شو د تادیې نور شرایط لکه A/S (د لید وروسته) خبرې وکړو.